Fancy a deep dive?

Carsten Krenz, Technical Director of STAUFF Germany, has given an interview for the trade magazine ‘fluid’. It contains further information about STAUFF's development and a look into the future. And the O+P also reports on the Schellen anniversary and our development:

Change in the Hydraulics Industry

A significant change is emerging in the hydraulics industry: OEMs (Original Equipment Manufacturers) no longer expect individual components alone, but complete, optimally coordinated system solutions. The benefits are obvious: fewer interfaces, higher efficiency, and a consistently high standard of quality. STAUFF recognized this trend early and evolved from a mere component supplier to a system partner for hydraulic lines.

The Origin: From the First Product to a Broad Product Range

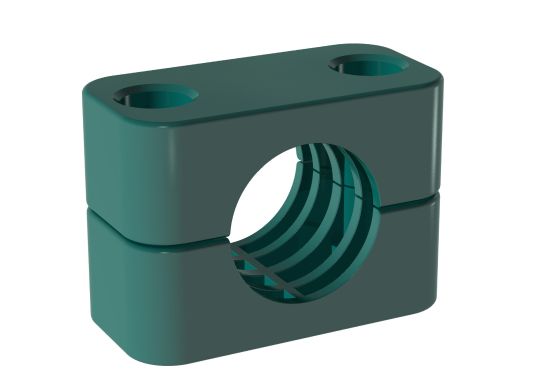

The success story began 60 years ago with a simple yet groundbreaking innovation: the green plastic clamp for particularly effective vibration reduction and damping. In the following decades, STAUFF evolved by continuously expanding its product portfolio from a one-component manufacturer to a provider of a complete hydraulic accessories program. Already in the 1970s, initial additions were made, always with the question: What else does the customer need?

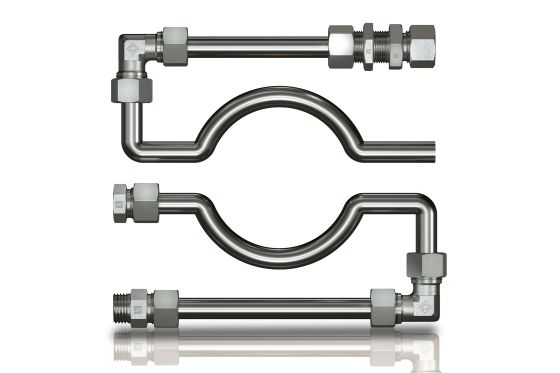

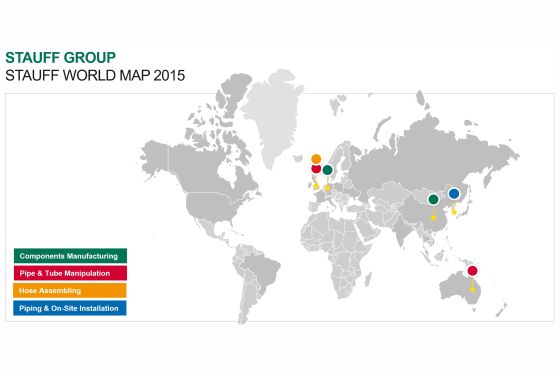

By 2010, STAUFF had expanded its portfolio alongside the proven STAUFF clamps with six additional product groups, including STAUFF Test, Filter, Diagtronics, Valves,Flanges and Hydraulic Accessories. The next major step came in 2015 with the introduction of STAUFF Connect, the company’s own pipe fitting program, as well as the acquisition of Voswinkel, a German quality manufacturer of hose fittings and quick-release couplings for hydraulics. With this, STAUFF definitively evolved into a full-range supplier capable of delivering all hydraulic line components from a single source.

From Full-Range Supplier to System Provider

The development into a system provider was achieved through a consistent expansion of service and manufacturing capacities. A key component of this strategy was the worldwide expansion of pipe and hose assembly. Today, STAUFF not only develops and produces individual components, but also delivers complete assemblies that are precisely tailored to the needs of OEMs.

The benefits for customers:

Uniformly high quality of all components

Reduction in the number of suppliers

Less coordination effort – one point of contact for the entire system

Optimization of costs and logistics through complete solutions

Central transfer of responsibility from connection to connection to a single responsible manufacturer

In addition to manufacturing, consulting and engineering services are also a central component of the full-liner strategy. STAUFF supports its customers not only in selecting the right components, but also in the optimal design of complete hydraulic systems.

Practical Example: How OEMs Benefit from STAUFF

A vivid example of successful collaboration with OEMs is the integration of STAUFF systems in the wind energy sector. The extreme conditions in this sector require reliable, long-lasting hydraulic solutions. Through customized piping systems and optimized mounting solutions, STAUFF was able to help reduce maintenance efforts and extend the lifespan of the installations.

Another area of application is electrically powered municipal vehicles, where noise levels must be minimized. Here, STAUFF NRC-Clamps(Noise Reduction Clamps) are used to dampen vibrations and thus enable quiet operation.

Future Strategy: Sustainability and Innovation

With the STAUFF Green initiative, the company is committed to sustainability and resource conservation. The goal is to operate CO₂-neutral by 2035 and reduce dependency on external energy suppliers.

Measures include:

Investments in energy-efficient production technologies

Installation of photovoltaic systems and combined heat and power plants

Use of absorption chillers for heat recovery

Development of new products from recycled materials, e.g. the first generation of clamps made from PP recycled granulate

With these measures, STAUFF ensures that it takes a leading role in the hydraulics industry, not only economically but also ecologically.

Why the Full-Liner Approach is the Future

The transformation from a pure component manufacturer to a system provider has proven to be a successful strategy for STAUFF. OEMs benefit from a comprehensive offering that includes not only products but also customized solutions and services. Close collaboration with customers, innovative strength, and sustainability make STAUFF a long-term, reliable partner in the hydraulics industry.

FAQs

What does it mean that STAUFF is a "Full-Liner"?

What benefits do OEMs gain from working with STAUFF?

OEMs benefit from consistently high quality, reduced complexity in the supply chain, optimized cost structures, and customized system solutions.

How does STAUFF contribute to sustainability?

Through the "STAUFF Green" initiative, the company invests in CO₂ reduction, energy-efficient manufacturing, and sustainable materials such as recycled plastics.

Which industries benefit particularly from STAUFF’s solutions?

STAUFF supplies numerous industries, including mechanical engineering, wind energy, construction machinery, agricultural technology, shipping, and electromobility.

gg

Newsletter Subscription

Receive automatic e-mail notifications about new posts on the STAUFF Blog